Embarking into the solar landscape, two formidable players stand tall: monocrystalline and polycrystalline solar panels. Unified by a common purpose — the conversion of solar energy into electricity — they diverge significantly in nuances. Selecting the superior choice becomes a nuanced task, with this article serving as your guide through the labyrinth of disparities.

A Swift Glimpse into Monocrystalline vs Polycrystalline Solar Panels

Diverging across material, cost, efficiency, performance, and appearance, monocrystalline and polycrystalline solar panels unfold a tapestry of distinctions. Each type boasts its unique merits and demerits, making a blanket superiority statement impossible. The right choice hinges on the specificity of individual needs.

Seeking Common Ground Before Delving into Disparities

Before delving into the distinctions, understanding the shared traits proves prudent.

Solar panels amalgamate various components — solar cells, a front-end glass coating, a rear-end polymer sheet, and an aluminum frame.

Both monocrystalline and polycrystalline share identical glass coatings, rear-end sheets, and aluminum frames. The sole demarcation lies in the solar cells, acting as the differentiating thread. It’s the solar cells that etch the boundary between the two, everything else from A to Z remains undifferentiated.

Monocrystalline panels, true to their name, harbor monocrystalline solar cells, while polycrystalline panels house their polycrystalline counterparts. These solar cells, comprised of thin layers of crystalline silicon, capture and convert light into electricity.

The solar cells emerge as the driving force behind the divergent properties and performance attributes of the panels. The subsequent sections dissect these distinguishing characteristics.

Material Musings

Monocrystalline solar cells boast monocrystalline silicon, while their polycrystalline counterparts stem from polycrystalline silicon.

Monocrystalline silicon flaunts a uniform and organized crystal structure, devoid of grain boundaries. In contrast, polycrystalline silicon, with its disoriented grain boundaries, lacks a specific orientation. To draw a technical distinction, monocrystalline is akin to a seamless, single-piece ice cube, while polycrystalline resembles clumped flake ice.

Cost Conundrums

Historically, the cost of monocrystalline silicon solar panels has consistently overshadowed polycrystalline’s. Rooted in the higher production cost of monocrystalline silicon — derived from polycrystalline silicon — this cost hierarchy persists.

Efficiency Echoes

As earlier alluded, the superiority of monocrystalline silicon manifests in its consistent thermal, crystal, and electrical properties throughout. The resulting minimum internal resistance facilitates superior efficiency, with fresh monocrystalline panels breaching the 20% efficiency mark, unlike polycrystalline panels, which linger below.

From 2006 to 2019, the efficiency graph mirrors monocrystalline’s perennial dominance over polycrystalline.

Performance Paradigm

For panels of equal size, monocrystalline outshines polycrystalline, courtesy of higher efficiency translating to more power. Temperature coefficients may slightly sway performance, but monocrystalline’s resistance to higher temperatures usually tilts the scale in its favor.

Aesthetic Allure

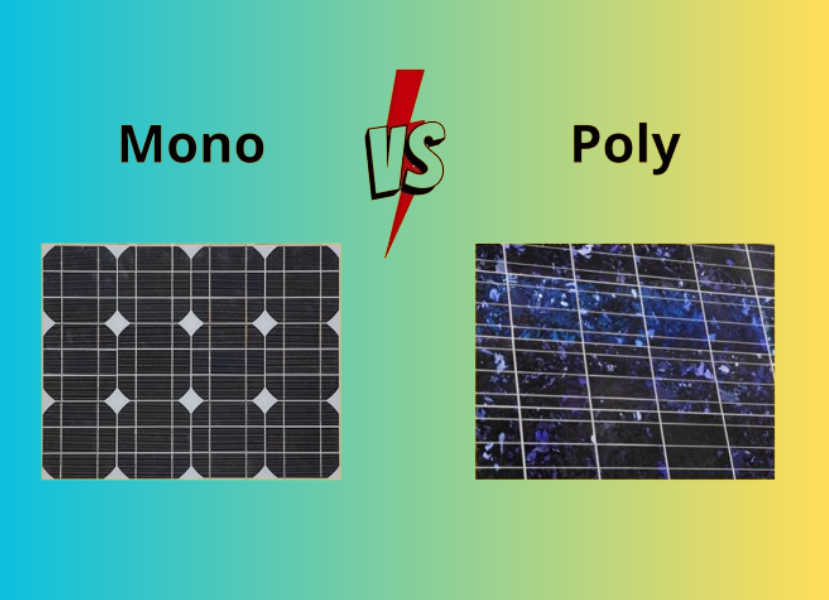

Aesthetics, a subjective realm, finds polycrystalline panels deemed unattractive due to their bluish hue and visible irregularities. Monocrystalline, boasting a homogenous black glossy hue, appeals more to the eye, elevating the perceived value.

Endurance Epilogue

Both types promise extensive lifespans, often backed by a 25+ years warranty for crystalline silicon solar panels.

Natural Rigidity

Both polycrystalline and monocrystalline panels exhibit rigidity, lacking flexibility akin to thin-film panels. This rigidity stems from the greater thickness of crystalline solar cells, prone to breakage rather than bending under deformative force.

Market Mosaic

Evaluating the market share unveils shifting dynamics. Monocrystalline’s reign in the 1980s waned, but a resurgence post-2015 saw it claim 65.6% of the global PV market in 2019, overshadowing polycrystalline’s 28.9%.

Decoding the full Solar Spectrum

Each type, laden with pros and cons, finds utility in various scenarios. Polycrystalline, though less efficient and more economical, thrives in spacious environments. Monocrystalline, pricier yet superior, excels when space is a premium or aesthetic appeal matters.

In the realm of RVs and boats, where space is a premium, monocrystalline emerges as the preferred choice. However, polycrystalline panels, with their cost-effectiveness, prove versatile for portable PV systems.

Considering the curved surfaces of vehicles, mounting structures become imperative for rigid crystalline silicon solar panels. Alternatively, flexible thin-film solar panels cater to the curvature seamlessly.

A cautionary note: the allure of monocrystalline panels may tempt overpricing. A judicious research endeavor is the beacon to navigate potential pitfalls in the market maze.